Materials for Cabinet Refacing Las Vegas

October 23, 2020Tips For Choosing Kitchen Cabinets

November 5, 2020Cabinet Refacing Materials Las Vegas

- |

- October 23, 2020

- |

- bsnva5

- |

- Commets are closed

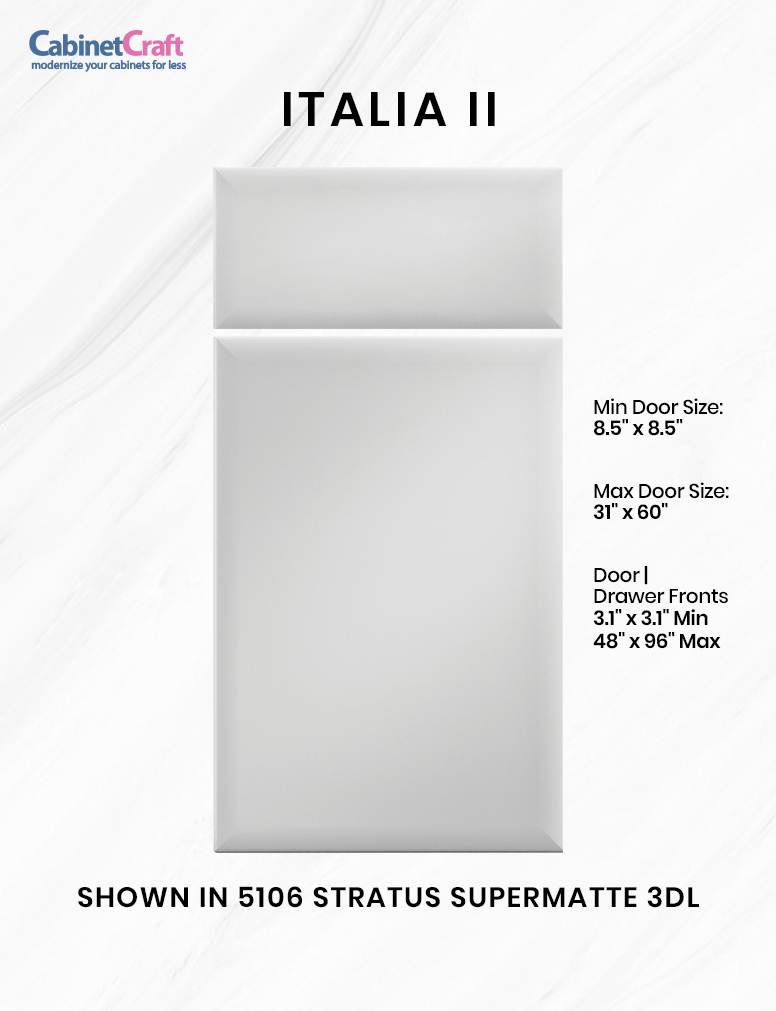

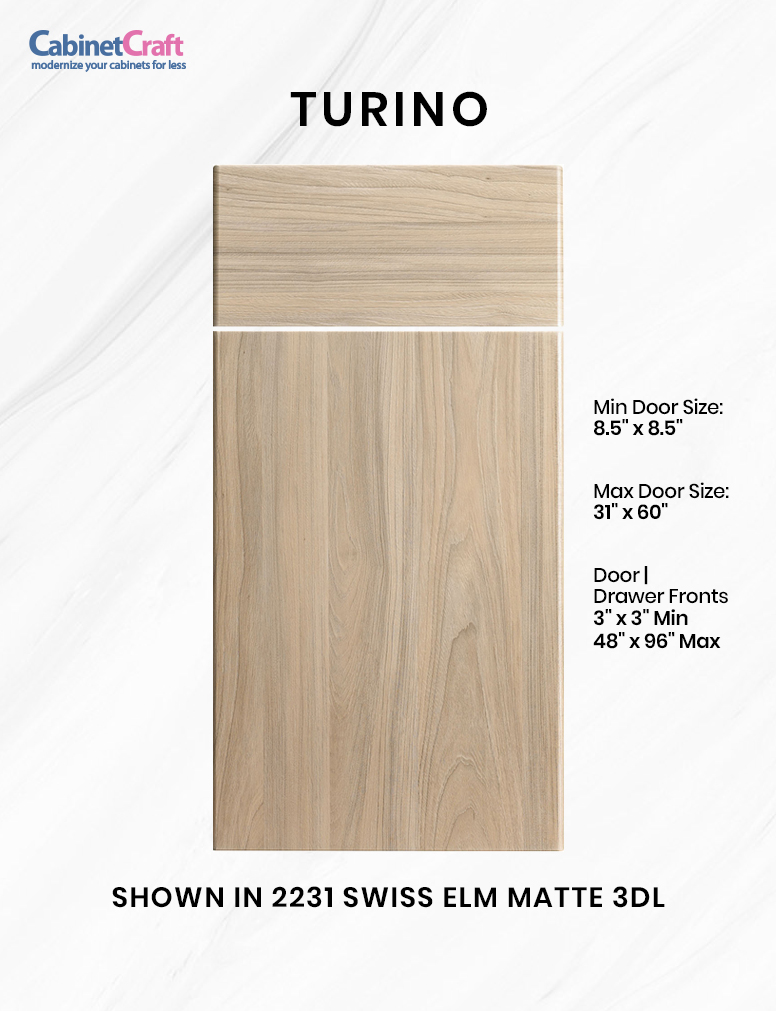

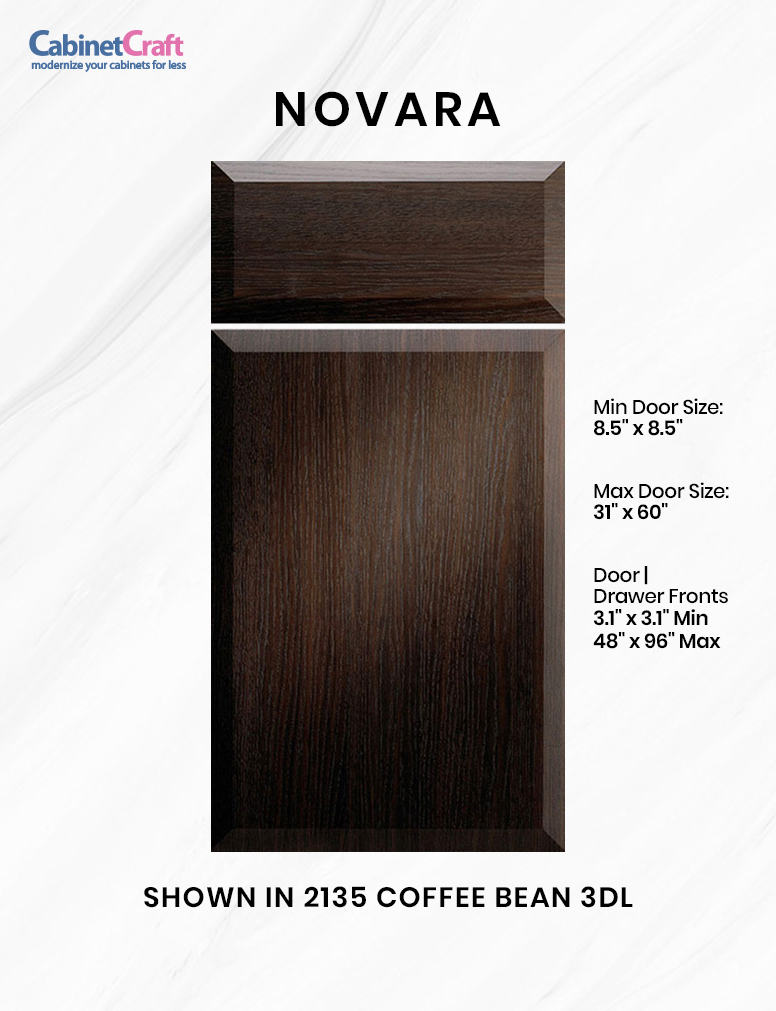

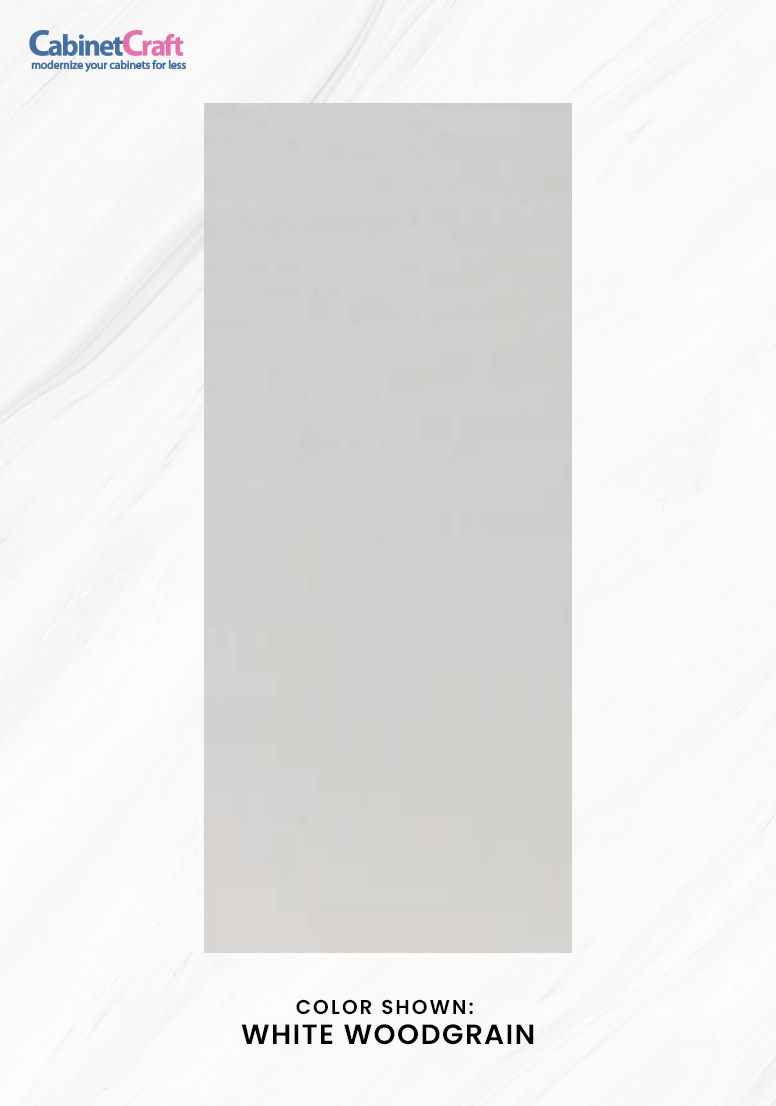

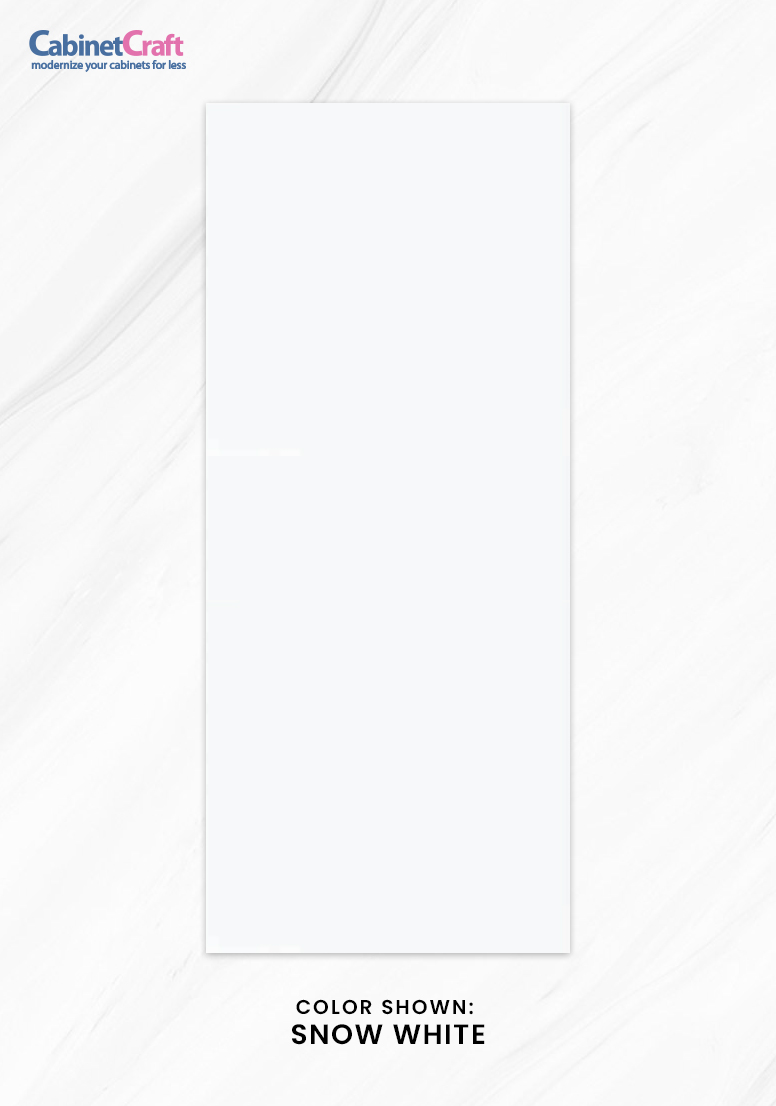

Cabinet Refacing Materials Las Vegas

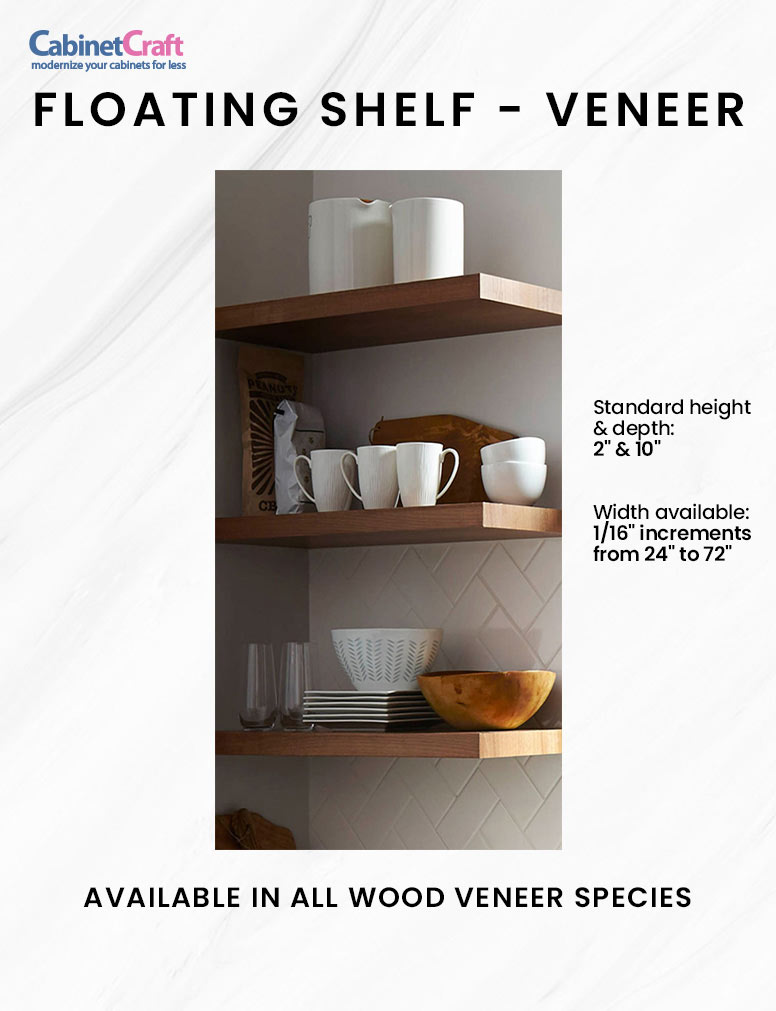

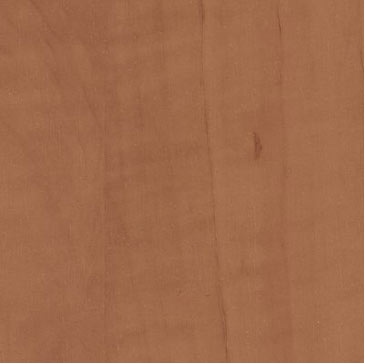

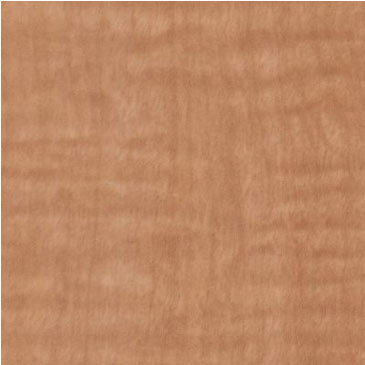

Cabinet refacing in Las Vegas, NV is a more economical and less messy alternative to kitchen cabinet remodeling, especially when your cabinet boxes are still in good shape. In refacing your kitchen cabinets in Las Vegas, it’s unnecessary to hire a professional who’ll reface your cabinets. Just learn how to be a DIYer, someone good at veneering (covering your cabinet boxes with a thin layer of wood or plastic called veneer).

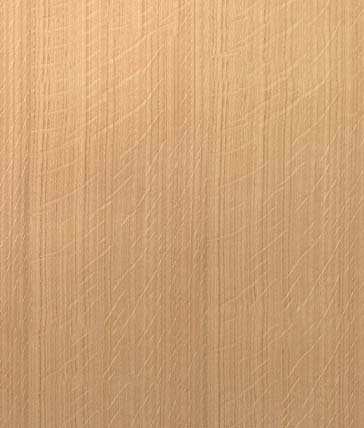

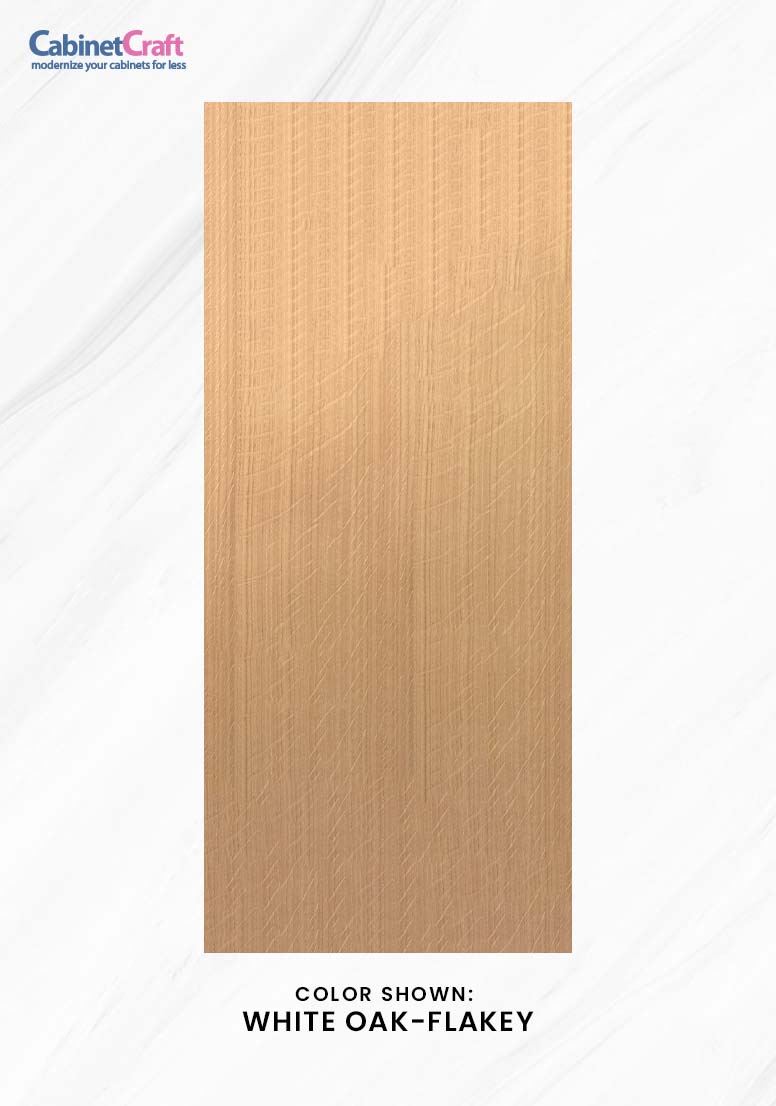

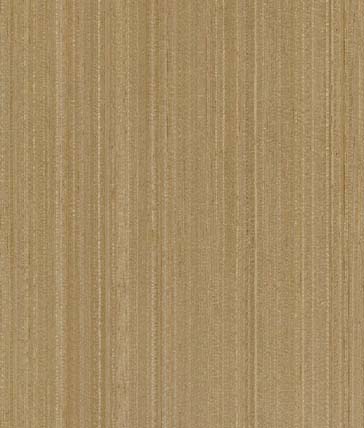

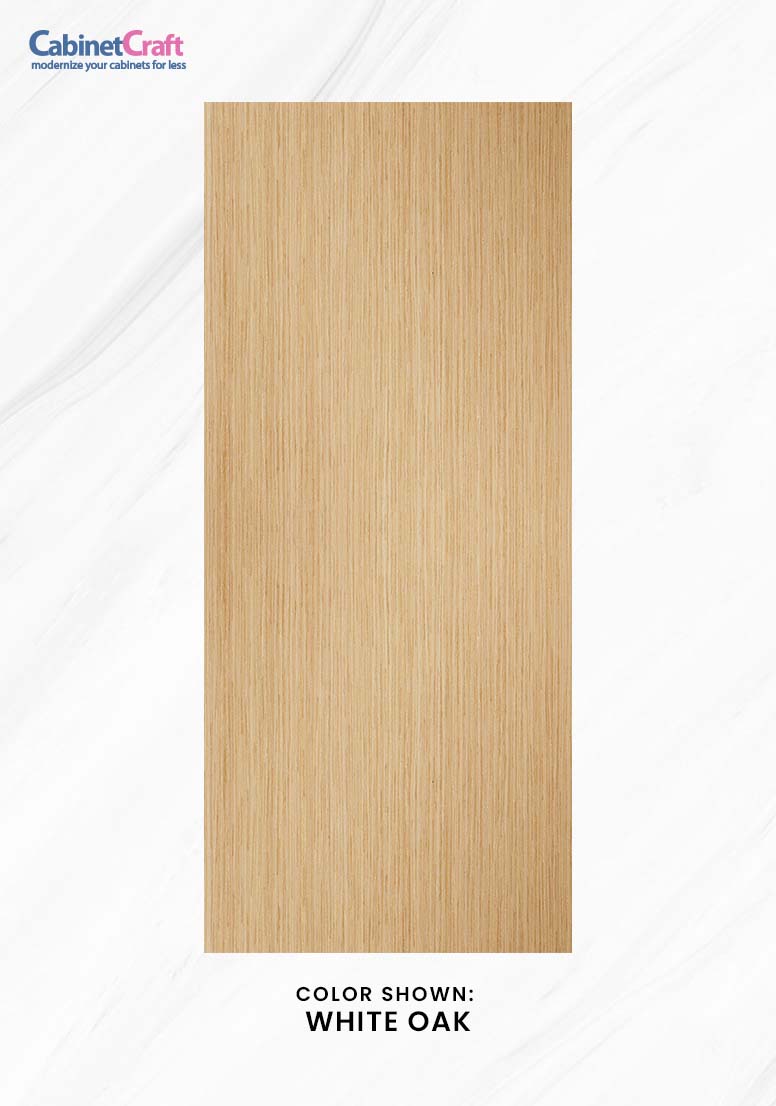

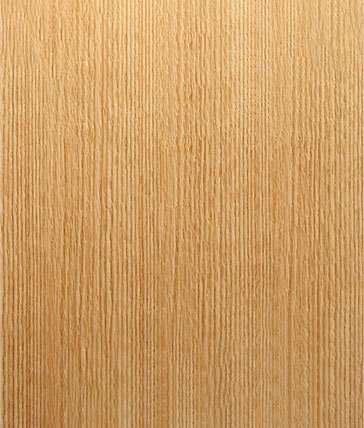

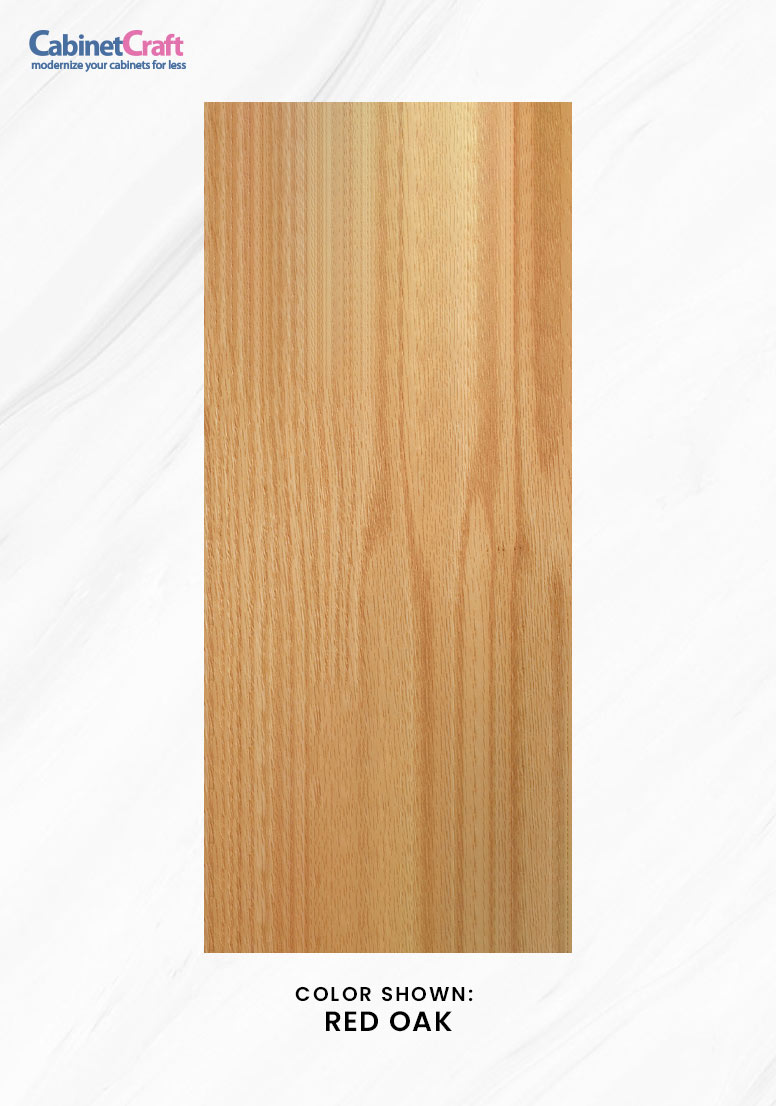

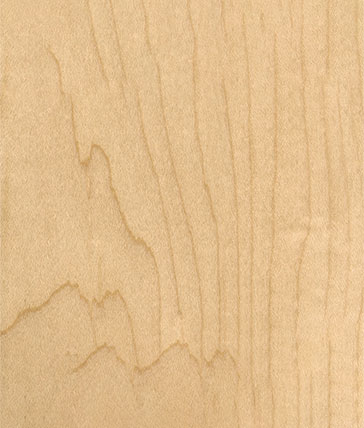

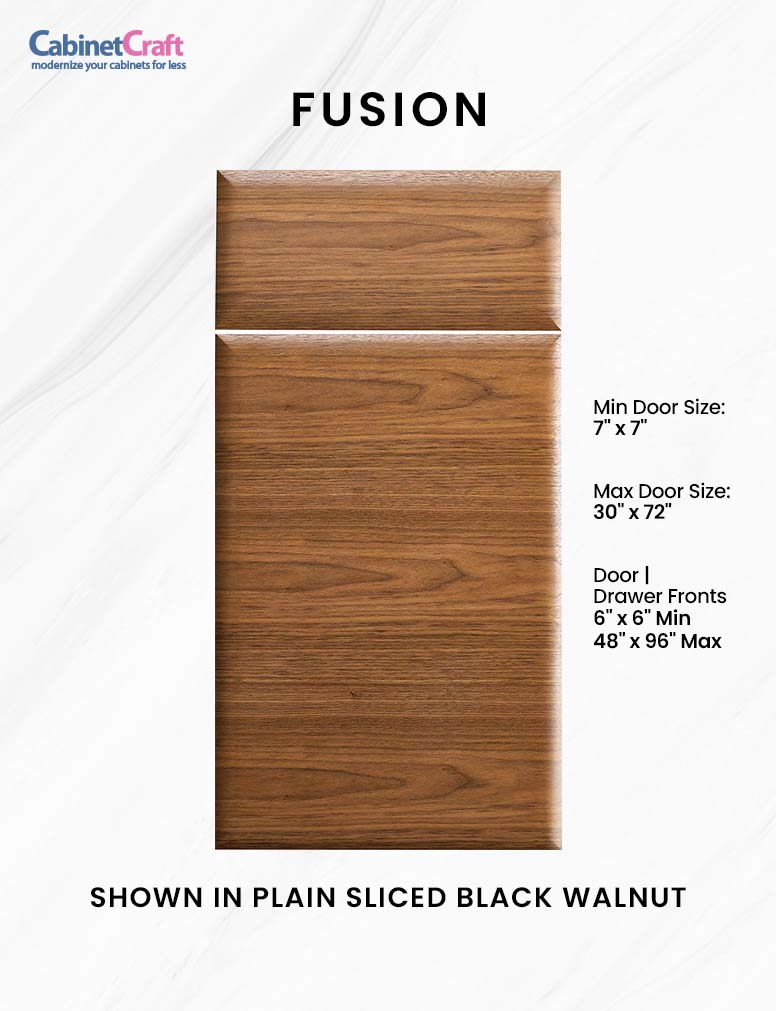

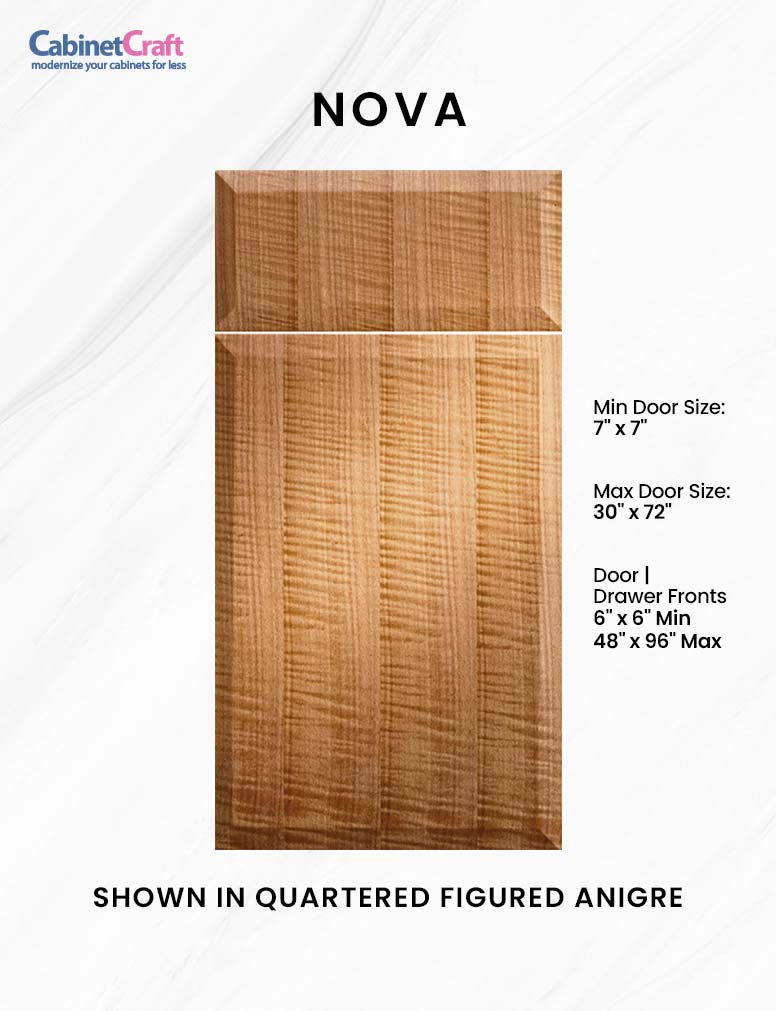

Among the most important things to consider in cabinet refacing are the materials you’ll use, specifically veneers, with high quality. All you need to know—from types of veneers (non-adhesive, pressure-sensitive-adhesive (PSA), plywood, and solid wood refacing stock) to installation—are here.

Non-Adhesive Veneers

Non-adhesive veneers are refacing materials that are thin and that need adhesive to be installed. They come in three types: paper back, wood back, and resin back.

Paper Back

A non-adhesive paper back veneer is the product of bonding a wood veneer and paper backing. This type is good for face frame applications though is not recommended for covering large surfaces.

Wood Back

A non-adhesive wood back veneer is a 2-ply one: the face is the wood species chosen by the customer while the back is a Luan veneer helping the sheet to be balanced. Unlike the paper back type, the wood back one is recommended for covering large surfaces.

Resin Back

As opposed to the first two types, the resin back one is stiffer, thicker, and more resistant to dents. The resin backing forms a barrier between the glue and the veneer that prevents any solvent-based products from affecting the finish.

Installation

Apply either solvent or water-based contact cement to install these types of non-adhesive veneers. For proper adhesion, use a veneer-smoothing tool.

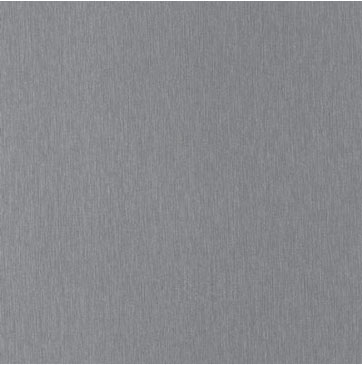

Pressure-Sensitive Adhesive (PSA) Veneers

Pressure-sensitive adhesive (PSA) veneers are also thin just like the non-adhesive ones though the PSA ones have 3M pressure-sensitive adhesive on their backs. PSA veneers come in two types: paper back and wood back.

Installation

It’s quite similar to non-adhesive veneers: use either solvent or water-based contact cement to install PSA veneers and a veneer-smoothing tool to properly adhere them to the cabinet boxes.

Plywoods

Plywoods come in 1/8” and 1/4”, both of which are available in either veneer or medium-density fiberboard (MDF) core. Moreover, one may opt to buy one type either unfinished or finished.

Veneer Core

On the one hand, 1/8” veneer core plywood can be used in all cabinet areas—fronts, backs, and under/sides. On the other hand, 1/4” veneer core plywood proves to be a good choice for strengthening cabinets with thin panels (both back and side).

Pin nails and panel adhesive can be used to install both 1/8” and 1/4” veneer core plywoods. Contact cement can also be used for the 1/8”.

Medium-Density Fiberboard (MDF) Core

However, medium-density fiberboard (MDF) core has a few drawbacks:

- the tendency to create more dust (when cutting)

- fractures (when pin nailing)

Just like the veneer core, the MDF one can also be installed through pin nails and panel adhesive.

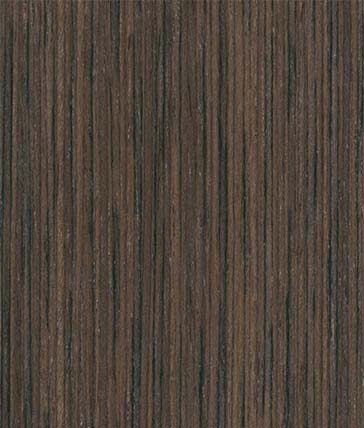

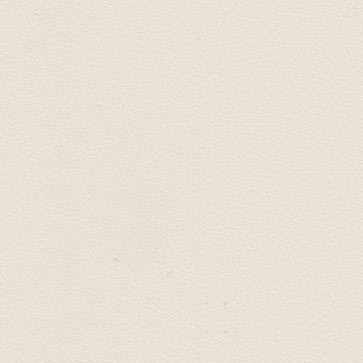

Solid Wood Refacing Stock

Solid wood refacing stock is recommended for face frame applications and is known for great features such as durability and reparability. This refacing material comes in the following:

- 1/8”

- 3/16”

- 1/4”

- 5/16”

- 3/18”

Each type’s thickness is at a width between 5/8” and 6”.